by Marshall Guillory

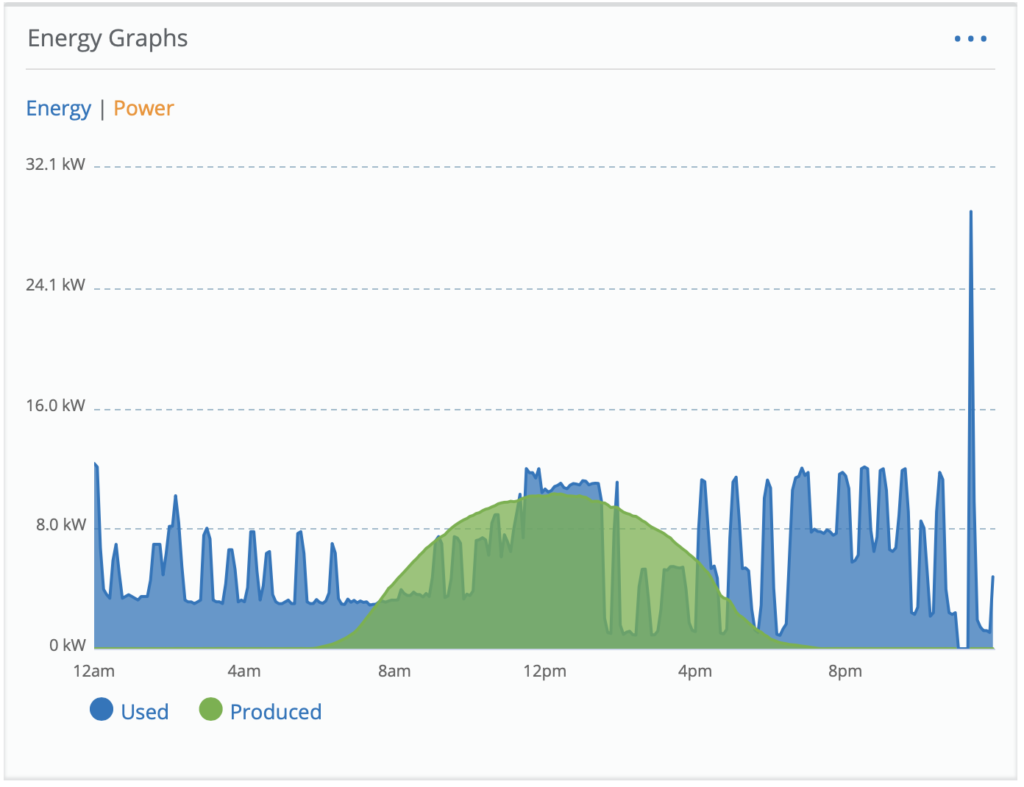

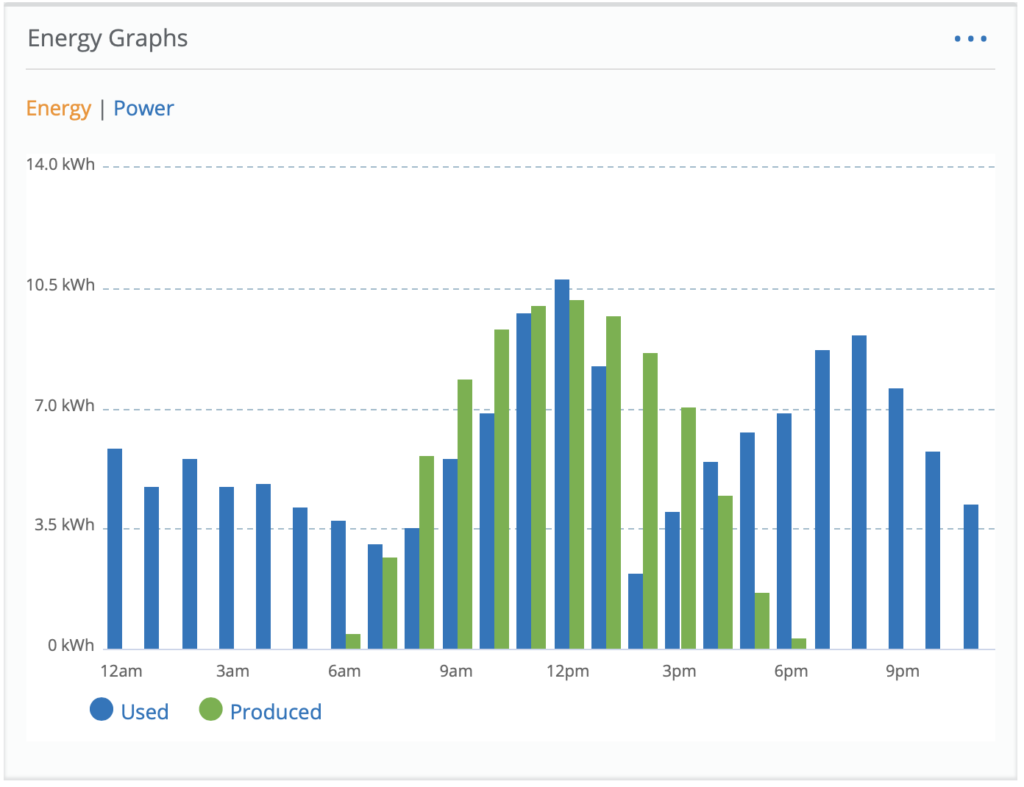

As with many of you, I often see parallels in personal paradigms within my work and observations in enterprises, markets, and business. These graphs of my newly installed solar system show a real example of a big struggle that enterprises face every day.

For context, I have a large family, and we also live in the desert, so air conditioning is very expensive. Hence the desire for a solar system to offset costs of consumption with a conservation benefit.

Matching production (i.e., business agility) with demand (i.e., customer-centricity) in highly complex or chaotic environments (Cynefin) threaded with some disorders (multi-domain exemplar) is a common challenge in business. Here are some interesting observations in the outcome of the operating system over the past week.

The central question here is: Does your business operate with the same patterns?

- Outcomes are fairly consistent given a running system absent change

- Production does not meet demand in the areas where there is high cost (3 pm-8 pm summer RCP; Cost of Delay!)

- The “Net” of production over time gives the illusion of valuable outcomes in the system.

- There is a clear misalignment of expected value, production, and a bottleneck evident in a system constraint that we cannot control (the Sun)

- Environment factors in the system change regularly (i.e., temperature|business context) but production is fairly static

Solutions

Now let’s explore some opportunities to improve the system. There is an assumption here that you have already taken steps to enable a continuous learning culture that relentlessly improves the system of systems.

Potential areas of improvement for each observation above:

Observation One

The outcomes were consistent in production, but this does not speak to quality, efficiency, or effectiveness in building and deploying value as a system. Individual components of the system may, in fact, be performing admirably while the system languishes in an unoptimized state.

The first step is to build in measurements into the system. We have to create a way to visualize how value is flowing through the system. Also, keep in mind that visualizing data from the past has limited value because of the “time to decision” factor. We really need organizational and value telemetry, not just post-production data.

There are various solutions in the marketplace to address building telemetry and also managing work. In the case of my solar system, the vendor provided a simple mechanism to do so. For your enterprise, you will need an agile lifecycle management tool combined with a value stream management solution that provides telemetry. We recommend our tooling partners including TaskTop Viz and Hub combined with implementation of the Flow Framework® to enable value stream telemetry.

Observation Two

In this system observation, we note that electricity production (or your companies widgets) did not occur in the most economically favorable period. The production of value did not reach the market in time to capitalize on our investment’s most effective return. In considering market rhythms like seasonal/holiday periods where demand is higher for certain products.

For business purposes, we must understand the various inputs to the economic decision-making framework to analyze the trade-off parameters to make the best economic decisions. This involves calculating the cost of delay.

In my solar electric system, market forces (power company contract for resale and wholesale purchase pricing) cause a higher cost consumption period (3 pm to 8 pm) in the afternoon to be mismatched with the high solar production period of 9 am to 3 pm. In business terms, this translates into poor utilization of resources like fractional allocation, over-utilization, and also faulty prioritization by ignoring the economic factors in product development. All of which result in poorer economic outcomes.

The net effect is that for businesses, they make less profit than they could have. For non-profits and government organizations get less business value for every dollar spent in appropriations and/or budgets.

If you consider shifting production opportunities to create more alignment and reduce the cost of delay in the system, a significantly higher value in outcomes could be achieved. This system leaves too much value opportunity on the table untapped.

Observation 3 – The Illusion

The “Net” of production over time gives the illusion of valuable outcomes in the system.

That was worth repeating. Assumptions are very dangerous things. Just because we deliver something does not equate to a valuable outcome in the system. Customers determine value. I’m often reminded of this with real estate examples. You may very well have put $100,000 in upgrades into your home. But, your home is only worth what the market will bear in terms of dollar value.

Likewise, provisional deliveries or integration of a product does not always equate to real-world value for customers. We must understand the customer journey through usage over time in the feedback loop before allocating value matrices. Imagine an NPS survey completed at the delivery point versus the same survey after the customer used the system for six months. Which is more valuable for ascertaining actual value delivered?

On numerous occasions, I have personally witnessed the emergence of “just get it done” or “it is good enough” attitudes that permeated product or service teams. These teams work really hard at producing the bare minimum. Customer-Centric organizations work hard to produce the maximum value for their customers.

Observation 4 – Understanding mis-alignment

There is a clear misalignment of expected value, production, and a bottleneck evident in a system constraint that we cannot control (the Sun)

In my personal example, I am at the mercy of a system constrained by a public utility company, local governments, technology, and finally, the system vendor and consequent support services and architecture. I obviously have a much easier time of it as compared to many enterprises.

To improve the system, we must first identify the constraint. The Theory of Constraints gives us an excellent thinking tool. First, let’s explore some thoughtful leadership on the topic.

The first step is to recognize that every system was built for a purpose. We didn’t create our organizations just for the sake of their existence. Thus, every action taken by any organ–any part of the organization–should be judged by its impact on the overall purpose. This immediately implies that, before we can deal with the improvement of any section of a system, we must first define the system’s global goal; and the measurements that will enable us to judge the impact of any subsystem and any local decision, on this global goal.

Goldratt, Eliyahu M.. Theory of Constraints . North River Pr. Kindle Edition.

Oftentimes we are blind to where the constraint is in our systems. Also, we are often wary of change that also leads to blindness to value determination. A third motive for failing to understand misalignment rests on our assumptions about what we may or may not change in the system. I like to remind organizations that organizations built the organization in the first place. People can change what people built.

Refocusing efforts at leaning out the system parallel with value stream management is an excellent way to catapult systemic changes forward while still maintaining a pace of change that is consumable in the organization.

Observation 5

Notice how environmental factors like weather and temperature changes did not linearly affect production. This monolithic behavior also exists in business, particularly in large enterprises, where the sheer mass of the system of systems and all its people keeps producing.

Even when the right thing to do was to pivot to other work.

Building a new culture and mindset with new thinking tools (Lean Startup; Horizons; Guardrails) about analyzing and prioritizing investments is critical to breaking monolithic behaviors. The wisdom of Eric Ries in the book, Lean Startup, combined with the critical depth of analysis and data-driven decision making described by Oosterwal and Dr. Allen Ward in The Lean Machine, cannot be understated.

Further study into portfolio concerns and connecting vision to market forces can be learned in Escape Velocity. Strategy cannot be blind to system constraints and must make visible the environmental (climate of business) factors that will affect your plans’ systemic change and tactical implementations.

The easiest way to visualize the underlying problem that undermines most portfolio strategies is to apply the filter of the Three Horizons model presented by Mehrdad Baghai and his colleagues at McKinsey in The Alchemy of Growth (Figure 2.4).

Moore, Geoffrey A.. Escape Velocity (p. 40). HarperBusiness. Kindle Edition.

Closing Thoughts

In the final observation and summary, we must acknowledge that we cannot rely only on what we know today. In terms of information and data used to make decisions and how we work, think, and feel. It is not always obvious where we should mine for value. There is also a common risk of falling into the illusion of creating value at the expense of your business and people.

We can avoid or minimize these problems by applying an array of knowledge, experience, and passionate, hard-working people, the ones you hired. Armed with these things and desire for change, you start the system. Then proceed through your patterns and cycles, observe, orient to outcomes, check, decide, plan, and act on relentless improvements.